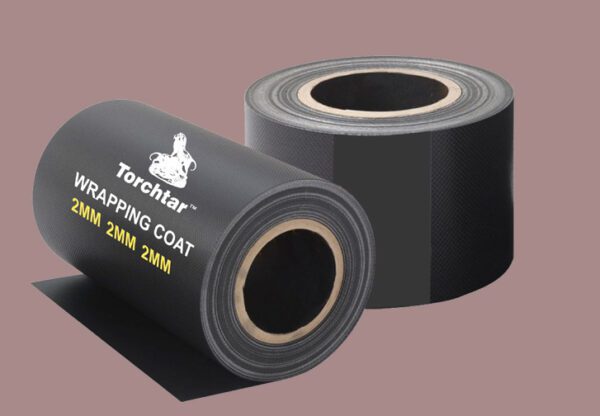

Wrapping Coat

Wrapping Coat

Torchtar Wrapping Coat is an Anti Corrosive tape based on Bitumen and specifically designed to comply with the requirements of IS: – . It incorporates a centre core of fibreglass tissues which lends mechanical strength, dimensional stability to the product. These centre cores are laminated with layers of coal tar or bitumen mix. The final product has a top and bottom layer of thermo fusible HMHDPE Film. These are high-performance anti corrosive pipe wrapping tape designed for use on buried pipelines, pipe joints, f ittings, and tie bars where impact or stress is high. It provides excellent protection against corrosion and electrolysis on below-grade metal substrates. TT Wrapping Coat is highly resistant to cathodic elasticity. This product can be used for the protection of butt weld joints against corrosion damage on concrete weight-coated submarine pipelines, where the joints will be in filled with hot marine mastic, PU foam, or other forms of infill material.

Get the professional solution for your requirement!

Fill the form below to book a free site evaluation by an Torchtar Service expert.

Product Overview

AREAS OF USAGE

- Below Ground. Flanges & valves, field joints, pipe couplings, cadwelds, bolted fittings, ductile/cast iron pipe.

- Above Ground. Steelwork Pipes, structural steel, flanges & valves, sweating pipe, tank bases, pipe bridges, cooling tower pipes and under thermal insulation.

- Jetty Piles and Marine Structures Steel, timber & concrete piles, submarine pipeline repairs, pipe hangers, risers, under decking piping, offshore platforms, H- piles, tie rods & end connections.

- Commercial and Residential Plumbing connections, cooling tower pipes, cable splices, roof repairs, waterproofing & sealing, battery terminals, threaded connectors, trailer axles & U-bolts.

Product Details

Additional information

| Colour/Form | Black, Roll |

|---|---|

| Packaging/Available Sizes | Available in ( Thick ness) 2 mm, 3 mm, 4 mm (Length) 10 m, (Width) 100mm, 150mm 200mm & 1 m |

| Applicable Standard | IS : 10221 : 1982 |

| Coverage | As Per Size |

| Shelf Life | 12 Months from the date of manufacture when maintain in protected storage in original unopened sealed condition at 5 – 40°C. |

| Storage Conditions | Store under cover out of direct sunlight and protect from extremes of temperature. In tropical climates the product must be stored in an airconditioned environment. Failure to comply with the recommended storage conditions may result in premature deterioration of the product or packaging. |

Product Application

SURFACE PREPARATION

Remove dust, flakes, oil, grease or other loose foreign particles by blasting, wire brush or compressed air. Leave 200 mm from pipe ends for welding joints. Coat and wrap such left over part of pipe at site after welding and hydro testing.

APPLICATION OF MATERIAL

Apply TT bitumen primer on cleaned surface at 0.3-0.5 L / m2. Allow the primed surface to touch dry, which may take 5 – 25 minutes. Show the torch flame on the surface of Wrapping Coat to get a soft smooth surface. Wrap the torched side of the

TT Wrapping coat on the primed surface. Provide overlap of 25 mm between two adjoining layers. Wrap spirally and apply sufficient tension to ensure good adhesion and avoid pockets and bridging to meet holiday detection requirement. Tape joint shall face downward on outside of lap joint.

Complete necessary welding and testing of the joint before coating.

Recommend to apply at the time of pipe erection and lowering inside trenches to avoid any damage.