Butyl Tapes

Butyl Tapes

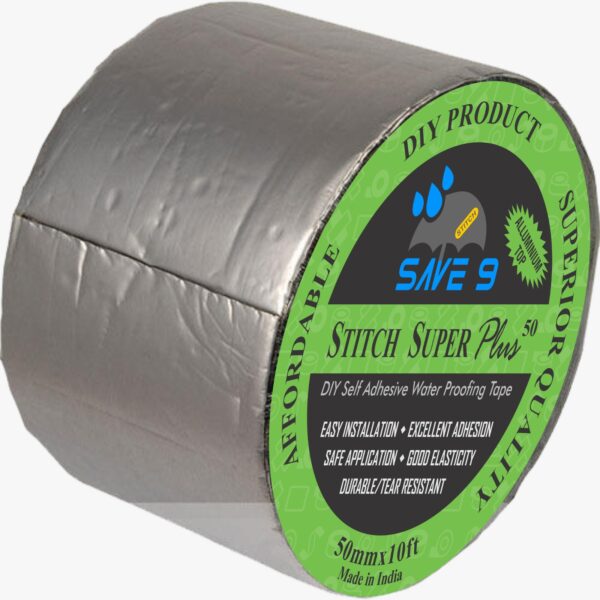

Butyl self-adhesive waterproofing tapes are a versatile and effective solution for sealing seams, joints, cracks, and overlaps in various construction applications. These tapes offer exceptional adhesion and long-lasting waterproofing capabilities, making them ideal for roofing, windows, cladding systems, and more.

Butyl Waterproofing Tapes are high-performance, self-adhesive solutions designed for sealing and waterproofing applications. Butyl tapes offer flexibility, and durability, making them ideal for a variety of construction and repair tasks.

Get the professional solution for your requirement!

Fill the form below to book a free site evaluation by an Torchtar Service expert.

Product Overview

WHY CHOOSE TORCHTAR

- Versatility: Our Butyl tapes can be used in a wide range of applications, both indoors and outdoors.

- Durability: Our Butyl tapes have long-lasting performance, even in harsh environments.

- Reliable Performance: Our butyl tapes ensure long-term waterproofing and protection.

- Ease of Application: Our butyl tapes are self-adhesive and easy to apply without special tools.

- Durable: Our butyl tapes resist environmental conditions, including UV rays, temperature fluctuations, and moisture.

- Support: We provide detailed installation guides and support.

KEY FEATURES

- Adhesive Power: Exceptional adhesion to various substrates including metal, glass, concrete, and plastic.

- Waterproofing Excellence: Provides a robust, watertight seal that prevents leaks.

- Temperature Flexibility: Remains effective in a wide temperature range, from -30 C to 100 C.

- Ease of Use: Simple peel-and-stick application; no special tools required.

Product Details

Additional information

| Colour/Form | Black/Grey/Silver |

|---|---|

| Available Packaging | Availabe Lenght 5M, Width: 2", 4", 6", Thickness 0.6 mm, 0.8 mm, 1mm, 1.2mm & 1.5mm |

| Resistant To | Weather, Water, Acidic or base solutions |

| Coverage | As Per Size |

| Shelf Life | 122 Months from the date of manufacture when maintain in protected storage in original unopened sealed condition |

| Storage Conditions | Store under cover out of direct sunlight and protect from extremes of temperature. In tropical climates the product must be stored in an airconditioned environment. Failure to comply with the recommended storage conditions may result in premature deterioration of the product or packaging. |

Product Application

Surface must be clean, dry, and free of oil, grease and dust. Position the Tape over the area to be covered. Peel off the release paper from the Butyl Seal Tape. Without stretching the tape, apply over the prepared surface area. Allow tape to lay naturally. DO NOT STRETCH TAPE. Press firmly over cracks and uneven surfaces. Apply the tape firmly, ensuring full contact with the surface. Smooth out any wrinkles or air bubbles.

Curing Time: Allow the tape to set for at least 4-6 hours before exposure to water or high stress.

Application Notes:

• Do not applying when it is raining, freezing or snowing.

• It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied be clean, dry, and free of grease or oil.

• Bond strength is dependent upon the amount of adhesive-to-surface contact developed.

• Note that different pressure, time and temperature on different (film / rigid) surface achieves different performance