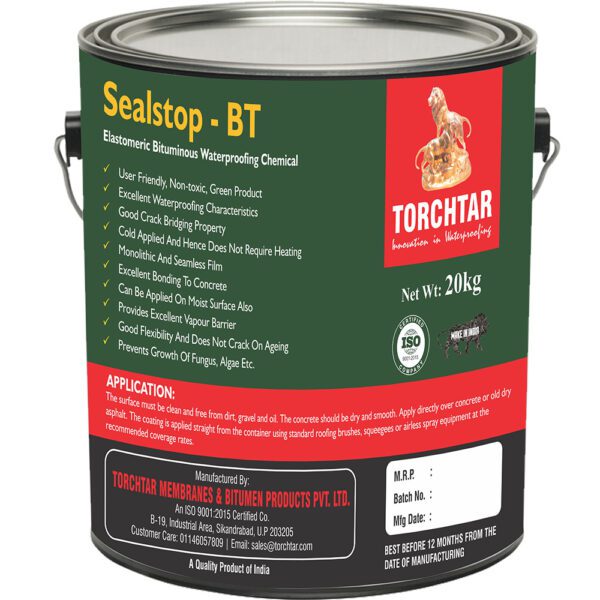

Seal Stop BT

Seal Stop BT

Torch tar Seal Stop BT is cold applied liquid rubberized liquid membrane, specially designed from a blend of modified bitumen, reinforced with special water repelling fillers, minerals, stabilizers and gelling agent. It is highly effective coating on damp new concrete structure as vapour sealer. Torchtar Seal Stop BT is particularly suitable for a wide range of applications including wet areas, foundations, basements, terraces, retaining walls, bridge abutments, planters, inverted roofs and remedial repairs to felt, asphalt, concrete, fibrous cement or other roof structures when protected from direct sunlight. It may be used in conjunction with a reinforcing fabric.

Get the professional solution for your requirement!

Fill the form below to book a free site evaluation by an Torchtar Service expert.

Product Overview

AREA OF USAGE

- Concrete structures for curing & waterproofing

- Metal structure as anti-rust coating &water proofing

- Sunken areas

- Roofs, walls or any structure as anticorrosion & protective waterproofing

KEY FEATURES

- User friendly, Non-toxic, Green product

- High elasticity, ensuring a permanently flexible barrier over a wide range of temperatures

- Ability to withstand expansion without cracking

- Low susceptibility to flow during hot weather temperature variations

- Resistant to sunlight

Product Details

Additional information

| Colour/Form | Grey, Liquid |

|---|---|

| Packaging | Available in 5 & 20 kg Drums |

| Coverage | 2 kg/m2 for 1.5 mm thickness in two coats |

| Shelf Life | 12 Months from the date of manufacture whenmaintain in protected storage in original unopened |

| Storage Conditions | Store under cover out of direct sunlight and protect from extremes of temperature. In tropical climates the product must be stored in an airconditioned environment. Failure to comply with the recommended storage conditions may result in premature deterioration of the product or packaging. |

Product Application

SURFACE PREPARATION

- All substrates must be sound, clean, dry, smooth and free from protrusions, voids, honey-combs and high spots. Presence of curing agent, paint and oil will impair adhesion. Fillets must be provided at corners or sharp angles using 4:1 sand and cement mortar modified with a good quality bonding agent.

- Stir Seal Stop BT by a slow speed mixture (approx. 400rpm) fitted with a suitable mixing paddle to ensure a homogenous mix.

- After stirring, wait for the product to settle in order to let entrapped air escape.

MATERIAL PREPARATION

PRIMING

Priming is not normally required on good quality, well prepared substrates.

CRACKS

All shrinkage and non-structural cracks must be treated with not less than mm coating of Torchtar Sealstop BT extending mm either side of the crack. Allow to cure overnight prior to general application.

APPLICATION OF MATERIAL

Seal Stop BT should be applied by brush to obtain a continuous unbroken film, after slightly dampening the surface. 2 coats are required with the second coat applied at right angles after the first coat has cured. Seal Stop

BT must be protected from mechanical damage during subsequent construction or backfilling works. Any damage may be repaired by spot application. If a water flood test to be run, the membrane should be cure

for a minimum of 10 days.

- Apply 1st coat of Seal Stop BT @ 0.25 kg/m2 by brush/roller.

- Apply 2nd coat of Seal Stop BT @ 0.25 kg/m2 by brush/roller.