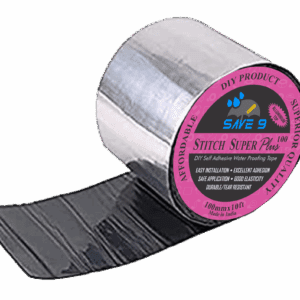

Roofing Felt

Roofing Felt

Roofing Felt is a lightweight, high-performance waterproofing sheet made from modified bitumen. It features superior adhesion, durability, and environmental compatibility, making it ideal for residential, commercial, and industrial applications. Its ease of installation and maintenance ensures long-term protection against water ingress.

Get the professional solution for your requirement!

Fill the form below to book a free site evaluation by an Torchtar Service expert.

Product Overview

USAGE AREA

- Residential Roofing

- Industrial Structures

- Basements and Foundations

- Waterproofing of Slabs

- Utility Structures

KEY FEATURES

- Waterproofing & Moisture Protection

- Increased Roof Lifespan

- Improved Weather Resistance

- Leak Prevention & Emergency Backup

- Enhanced Fire Resistance

- Prevents Ice Dams Formation

- Easy Installation & Cost-Effective

- Better Adhesion for Shingles

Product Details

Additional information

| Form | Roll |

|---|---|

| Colour | Silver |

| Available Sizes | 0.8mm, 1mm, 1.5mm, 2mm Thickness & 1m x 20m Length |

| Coverage Area | As per Size |

| Shelf Life | 1 Year |

| Storage Condition | Store under cover, out of direct sunlight & protect from extremes of temperature. In tropical climates the product must be stored in ambient environment. Failure to comply with the recommended storage conditions may result in premature deterioration of the product. |

Product Application

Surface Preparation

Clean the substrate thoroughly to remove dust, oil, grease, and loose particles. Repair any cracks or voids for a smooth and uniform surface.

Priming

Apply a compatible bituminous primer (0.3-0.4 liters per square meter) evenly using a brush, roller, or spray. Allow the primer to dry completely before membrane application.

Membrane Installation

- Unroll roofing felt and align it on the primed surface.

- Heat the underside of the membrane using a gas torch until it becomes tacky.

- Press the membrane firmly onto the substrate and smooth out air pockets.

- Overlap adjacent sheets by at least 75 mm on the sides and 100 mm at the ends to ensure proper sealing.

Corners and Details

Pay special attention to edges, corners, and penetrations by reinforcing with additional membrane layers or sealing tape for a watertight finish.

Finishing

For exposed areas, apply a reflective coating like aluminum paint to enhance UV resistance. For trafficable areas, overlay with tiles or a concrete screed for added protection.

Precautions

- Avoid overheating the membrane during torching to prevent damage.

- Work in well-ventilated areas to minimize exposure to fumes.

- Use appropriate personal protective equipment, including gloves and goggles.

- Store the product in a vertical position, away from direct sunlight or heat.

- Follow the manufacturer’s application guidelines for optimal performance.